DEPARTMENTS

Research and Development

Improve the quality of products and services

New product introduction to the company product portfolio

Develop and provide technical knowledge for industrial designs

Practical research in the required fields by related industries

Research and Development

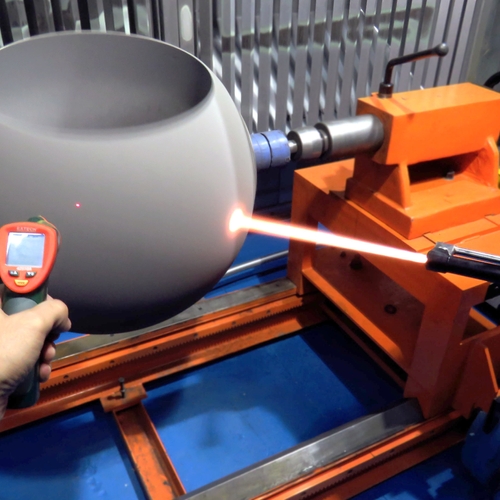

Coating HVOLF

Ball Coating with grinding to 32’’ diameters

Cylindrical component coating to 6000 mm

testCoating of Plate or smooth pieces to 6000 mm length & 2000 mm width

Exclusive Engineering & QC system for Coating

Commonly Sprayed coating materials including cermets ( WC-Co,WC-Co-Cr) Chrome Carbide, MCrALY, Colmonoy (Nickel alloy). Stellite (Cobalt alloy).

Coating HVOLF

Production

Grinding

Pattern Making

Production of all mechanical parts of valves

Painting

Valve testing

Packing

Production

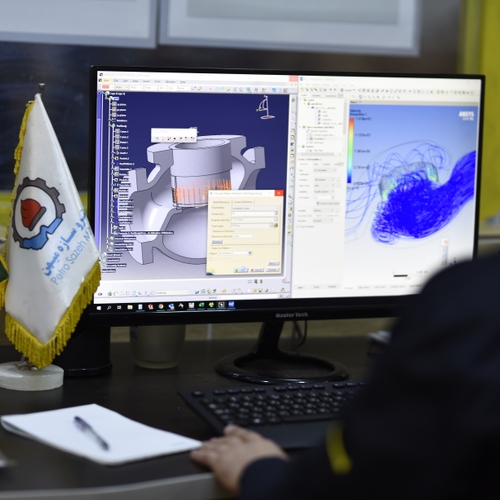

Engineering

PSM designs is a combination of proven engineering expertise with state of state-of-the-art technology

PSM engineers use advanced technical software & standards

PSM employs its exclusive control valve sizing software

Engineering

Quality Control

Hardness Testing

Paint Thickness Testing

Leakage Test

Hydro Test

Loop Test

Torsion Testing

Dimensional Testing

Fugitive Emissions Testing

Pipe Wall Thickness Testing

Quality Control

Repair & Maintenance

Testing all types of valves up to 42 inches and 2500 Class according to industry-accepted standards

Testing all types of control valves according to industry-accepted standards

Performing hydrostatic and leakage tests

Reconstruction and repairs of all types of valves following the appropriate standards and requirements

Manufacturing spare parts for all kinds of valves

Repair & Maintenance